$8.90 Original price was: $8.90.$6.40Current price is: $6.40.

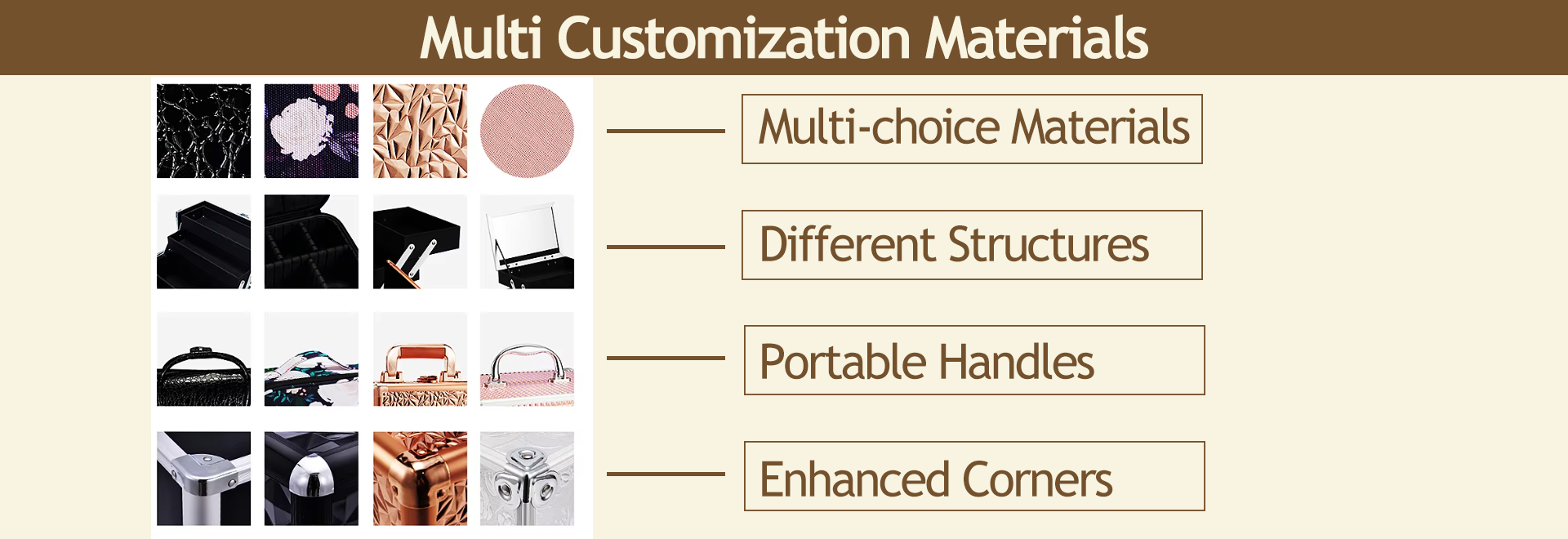

1. Color: Black is the regular style, others are pink, champagne and so on

2. Surface Material:You can choose which you want to wholesale

3. Lining Material: Polyester fiber are common materials, and there are also PU and so on.

4. LOGO: No LOGO is a regular model, you can customize your LOGO

5.Handle:A variety of handle styles for you to choose

6. If you have your own design style for the travel Luggage, please provide drawings to us, we will realize your ideas through3D drawings

Click it>>>>>>>>Catelogy

Packing list

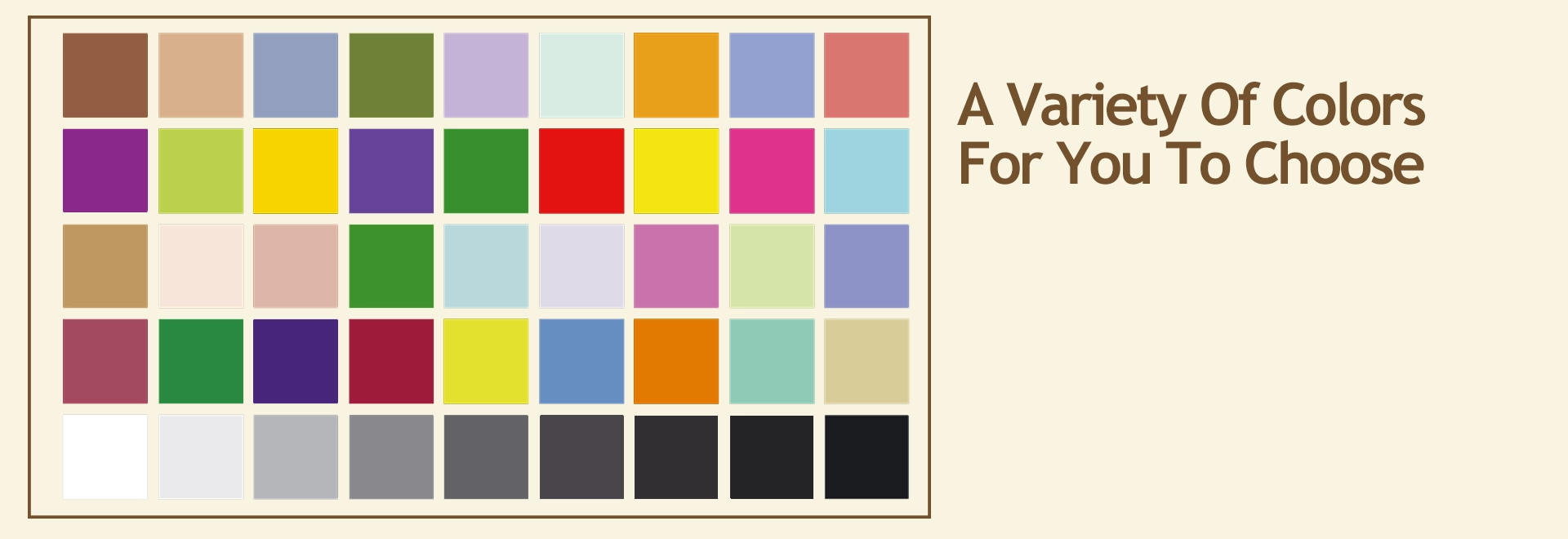

In the cosmetic case market, product packaging design plays an important role in attracting consumers. Among them, packaging color is a key factor because it can directly affect consumers’ emotions and purchasing decisions. So, how should the color of cosmetic packaging be chosen? This article will provide you with some valuable suggestions.

1. Understand color psychology

When choosing the color of a cosmetic bag, you first need to understand the basic principles of color psychology. Different colors can trigger different emotions and associations in people. For example, red is often associated with passion, vitality, and love, while blue gives people a sense of tranquility, trust, and technology. Green is often associated with nature, health, and freshness, and purple often represents luxury, mystery, and elegance. Understanding these principles of color psychology will help you position your products more accurately and attract target consumers.

2. Analyze the target market

When choosing the color of a cosmetic bag, you need to have a deep understanding of your target market. Consumers of different ages, genders, and cultural backgrounds may have different preferences and sensitivities to colors. For example, young consumers may prefer bright and bold colors, while mature consumers may prefer soft and low-key colors. Therefore, understanding the preferences and needs of your target consumers through market research and analysis is the key to choosing the color of the bag.

3. Brand Recognition and Consistency

The color of the cosmetic bag should be consistent with your brand image and positioning. Choosing a color that is highly recognizable to your brand will help consumers recognize your product at a glance among many products. At the same time, maintaining the consistency of the bag color will also help strengthen the brand image and increase consumer loyalty to the brand.

4. Product Features and Efficacy

The color of the cosmetic bag should also be consistent with the product features and efficacy. For example, if your product is a skin care product designed to relieve fatigue, it may be more appropriate to choose a color with a sense of tranquility and relaxation, such as green or blue. If your product is a cosmetic that emphasizes vitality and youth, bright colors such as red and orange may be more suitable. Conveying product features and efficacy through the color of the cosmetic bag will help consumers understand your product faster and generate a desire to buy

5. Market Trends and Competitors

It is also very important to pay attention to market trends and competitors’ packaging color choices. Understanding the current popular cosmetic bag colors and design elements can keep your products competitive in the market. At the same time, observing the color strategy of your competitors’ cosmetic bags can help you find a differentiated design direction to stand out in the market.

In summary, the selection of cosmetic bag color is a comprehensive process that needs to consider multiple factors such as color psychology, target market, brand identity, product characteristics, and market trends. By deeply understanding and analyzing these factors, you can choose the right bag color for your cosmetics, thereby attracting more consumers and improving the market competitiveness of your products.

Today, customers are increasingly striving to satisfy their own individual needs and requirements when making purchases. According to a Deloitte study, in some categories, more than 50% of consumers express interest in purchasing customized products or services. Manufacturing customized products requires focusing on specific customer requirements, but applying this to potentially thousands of orders significantly increases production costs and lead times using traditional methods. Mass customization is a process that combines the personalization of customization with the advantages of mass production to meet changing customer needs.

Today, customers are increasingly striving to satisfy their own individual needs and requirements when making purchases. According to a Deloitte study, in some categories, more than 50% of consumers express interest in purchasing customized products or services. Manufacturing customized products requires focusing on specific customer requirements, but applying this to potentially thousands of orders significantly increases production costs and lead times using traditional methods. Mass customization is a process that combines the personalization of customization with the advantages of mass production to meet changing customer needs.

The figure below clearly illustrates the HX Leather Goods ordering and importing procedures. If you read it carefully, you will find that the ordering procedures are carefully designed to ensure that your interests are well protected. And the quality of the boxes is exactly what you expect.

Customized services include:

1. Color: Black is the regular style, others are pink, champagne and so on

2. Surface Material:You can choose which you want to wholesale

3. Lining Material: Polyester fiber are common materials, and there are also PU and so on.

4. LOGO: No LOGO is a regular model, you can customize your LOGO

5.Handle:A variety of handle styles for you to choose

6. If you have your own design style for the travel Luggage, please provide drawings to us, we will realize your ideas through3D drawings

We are a manufacturer of OEM/ODM custom makeup bags and cases that can be produced to your original design or private label.With OEM cosmetic bags, the brand or company provides the manufacturer with the design or specifications for the bag, which is then produced and branded with the company logo or name. ODM cosmetic bags, on the other hand, involve the manufacturer designing the bag to the company’s specifications, which is then produced and branded for the company. OEM/ODM cosmetic bags allow brands and companies to create unique custom bags, which helps increase their brand recognition and visibility. These bags can be designed to specific requirements, such as size, shape, and color. And can be made from a variety of materials, such as leather, synthetic fibers, or natural fibers

The following is an OEM/ODM process solution, the specific steps are as follows:

1. Demand analysis: Communicate with customers to understand their needs and requirements. Including product function, design requirements, expected output, price budget and so on.

2. Design stage: In the case of new product design, the design stage is carried out. The design stage includes product conceptual design, structural design, etc. The oem needs to communicate with the customer about the relevant information of the logo, including the printing method, material and location, while the odm needs the customer to provide drawings or communicate with each other in detail about the relevant requirements for design.

3. Sample production: According to customer needs, produce samples for their evaluation. Sample production requirements meet the requirements of the customer.

4. Sample confirmation: The customer evaluates and confirms the sample, including product performance, appearance, function and so on. Make necessary adjustments and modifications based on customer feedback.

5. Mass production preparation: After sample confirmation, mass production preparation is carried out. This includes selecting material and component suppliers, establishing supply chains, and developing processes and production processes.

6. Trial production: Conduct small batch trial production to test the problems and risks in the production process, and optimize and adjust the production line.

7. Mass production: large-scale mass production is carried out according to the feedback results of the trial production stage. Ensure product quality and production to meet customer demand.

8. Quality control: Establish a quality control system to monitor and control the production process to ensure the stability and consistency of product quality.

9. Product testing: carry out various tests and inspections on the products produced to ensure that the products meet the standards and real requirements.

10. Packaging and shipping: The product packaging, according to customer requirements for customized packaging to complete the product shipment and delivery.

11. After-sales service: Provide after-sales service, including maintenance, technical support, training, etc. Ensure customer satisfaction in the process of using the product.

12. Continuous improvement: According to market feedback and customer requirements, continuous improvement and innovation of products to meet market needs.

The above is a common 0EM/0DM process solution, each step is very important to ensure that the customer’s needs are met, the quality of the product and the delivery time are guaranteed. At the same time, the process plan can be adjusted and optimized according to different industries and products to adapt to different needs and markets.

Innovation, excellence and reliability are the core values of our company. These principles are today more than ever the foundation of our success as an internationally active medium sized company Cosmetics OEM/ODM supplier Canvas Bags, and we believe that now we are well equipped to provide you with satisfactory goods. Eager to collect something of your requirements and generate a long-term partnership. We solemnly promise: the same quality, more favorable prices; Same price, higher quality.

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

All of our products are available for sampling